Is CNC Lathe Service Expensive?

When considering CNC lathe services, the cost can sometimes leave you wondering if it’s worth the investment, especially if you’re unfamiliar with how they work. The truth is that pricing depends on several factors, from the material you’re using to the complexity of the part you’re machining. It’s not just about the hourly rate; the precision, time, and expertise required all play a role in determining the final cost. Keep reading this article as we’ll explore CNC lathe services in more detail and what influences the cost. This way, you’ll understand why prices vary and how to maximize your budget while ensuring you get quality results.

Overview of CNC Lathe Service

CNC lathe service is an essential process in manufacturing, where manufacturers use computerized machines to shape materials with incredible precision. Unlike traditional lathes, CNC (Computer Numerical Control) lathes automate the turning and cutting process, improving accuracy and efficiency.

You can expect consistent quality, whether producing a single part or running large batches. This reduces the risk of defects and wasted materials, saving time and money in the long run. Additionally, the automation involved means that production can run continuously. Thus, this, in turn, helps increase output without comprising accuracy.

How Does CNC Lathe Service Work?

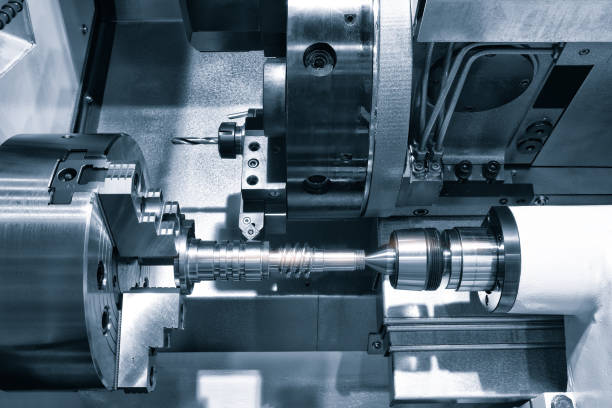

the CNC lathe machine face cutting the metal shaft parts

In a CNC lathe, the material, usually metal or plastic, gets mounted and rotated at high speeds. The cutting tools, controlled by computer commands, remove material to create the desired shape. This process allows you to fabricate simple, complex parts with minimal manual intervention. Designs can be programmed into the machine, ensuring that each part is identical and meets precise specifications.

CNC lathe services are commonly used to produce cylindrical components such as shafts, bushings, and fittings. However, with advanced capabilities, CNC lathes can also create more intricate parts that would be challenging to make manually. This makes them a vital tool in many industries like aerospace and automotive.

How to Calculate CNC Lathe Service Cost

the CNC lathe machine milling cut the metal shaft parts by milling spindle

Understanding CNC lathe service costs requires considering several key factors that impact the price. Many elements contribute to the overall cost, from the type of material you choose to the complexity of the part and the finishing touches you want.

Let’s examine each factor determining the price of CNC lathe services in more detail and discuss how you can manage your budget effectively.

Material Costs

The first thing to consider is the material you work with. CNC lathes can machine a wide range of materials, from common metals like aluminum, stainless steel, and brass to more expensive materials like titanium and carbon steel. Each material has its price based on availability and properties. For example, aluminum is lightweight and affordable, making it a common choice for parts that don’t require extreme strength. In contrast, titanium is strong and resistant to corrosion but comes at a much higher price due to its scarcity and the difficulty in machining it.

In addition to the base material cost, larger or thicker parts require more raw material, which increases the cost. Therefore, it’s important to pick the right material for your project based on its purpose, but also keep the budget in mind.

Complexity and Design of the Part

Next, consider the complexity of the part you intend to fabricate. Simple parts with basic shapes and fewer operations, like cylindrical shafts or spacers, tend to be faster and cheaper to machine. However, as your design becomes more intricate, featuring undercuts, tight tolerances, or fine details, the cost rises. Complex parts often require more advanced programming, multiple tool changes, and extra setups to ensure precise machining. As a result, the added time involved significantly impacts both machine usage and labor costs.

Machine Time and Labor Costs

Generally, the time the machine needs to produce your parts impacts the cost. Machine time varies depending on the size, shape, and complexity of the part. Simple jobs can be completed quickly, while complex parts may take several hours or even days. On top of that, you’ll need to account for the labor involved. CNC machines are automated, but skilled machinists must set up the machine, input the programming, load the material, monitor the process, and check the parts for quality. Hence, the more intricate the part or the higher the precision required, the more time and expertise the machinist needs, which increases labor costs.

Customization, Post-Processing, and Finishing

Many CNC lathe parts require more than just the initial machining. Post-processing steps like heat treatment, anodizing, polishing, or coating add both functionality and appearance to your parts but come with additional costs. For instance, parts that need to be rust-resistant or have a specific aesthetic look often go through surface treatments like powder coating or anodizing. More so, specialized features like threading, engraving, or knurling, applied to some parts, also add to the machining time. So, while these customizations improve the final product, each additional process adds time and cost to the overall service.

Volume of Parts Produced

The number of parts ordered can significantly influence the cost per part. Producing large batches reduces the setup cost per unit. This is why ordering in bulk usually results in a lower cost per part compared to small production runs. For custom or prototype parts where you only need a few pieces, setup costs can make up a large portion of the total price. If you’re able to, scaling up production can greatly reduce costs. Many CNC service providers offer discounts for bulk orders because, after the initial setup, the machine can run multiple parts in a single cycle with minimal adjustments. This efficiency leads to lower costs for the manufacturer, which can be passed on to the customer.

Lead Time and Rush Orders

How quickly you need your parts can also affect the price. Standard lead times may range from a few days to a couple of weeks, depending on the workload and complexity of your project. If you require a faster turnaround, rush orders usually come with a premium charge. This is because manufacturers may need to rearrange their production schedule or work overtime to meet your deadline. That said, planning ahead and giving your manufacturer ample time to produce your parts can save you from extra rush fees.

Location and Shipping Costs

The location of the CNC lathe service provider can influence costs. CNC machining services are available worldwide, but prices vary based on the region. Providers in countries with lower labor costs, such as China, often offer affordable services, but you must also consider shipping costs, especially for heavy parts. Shipping large or heavy parts internationally can add significant expense. Be sure to factor in not just the service cost but also how much you’ll pay to get the parts to your location safely and on time.

Conclusion

Navigating the costs of CNC lathe services doesn’t have to be complicated. It’s important to consider various factors like the type of material, the complexity of your designs, and the time required for labor. Remember, custom features and finishing touches will add to your total expenses, so plan accordingly. If you’re looking to save, consider ordering larger quantities, as this often reduces the cost per piece. By keeping these points in mind, you can better manage your budget and get the best value for your CNC lathe services.

At Zintilon, we offer top-notch CNC lathe services tailored to your needs. Don’t let costs hold you back from achieving your goal. Contact us today for a quote and see how we can help you get the best value for your CNC milled and turned parts!